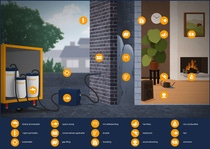

Discover the 3-component system for manufacturing clay foam

Construction

Cavipor® – Clay Foam Insulation

The mineral-based in-situ foam system for safe and sustainable insulation.

Cavipor® was specially developed for the energy-efficient renovation of double-wall masonry. With its unique combination of properties, Cavipor® opens completely new possibilities for the construction industry.

When clay meets water, air and our technology, something unique is created: clay foam – a versatile insulation solution that fits seamlessly into the smallest cavities.

Easy processing and seamless filling

The Cavipor® system combines the advantages of a mineral based insulation material with the simple, safe, and clean processing of a foam system. The water-based components can be transported and processed dust and fiber-free, offering 10x the foam volume after being expanded with air. The fresh foam is injected into the cavity wall through small filling holes, where it does not expand further or build up internal pressure. The foam's flow properties ensure that it fills the cavity layer seamlessly − largely independent of the layer's thickness and any narrow areas.

Self-sealing foam with optimal insulating properties

Cavipor® foam is self-sealing. It is prevented from exiting through small holes and cracks in the wall, and no preliminary work or reworking is generally necessary. The fresh foam already offers good insulation capabilities at this point. After the drying process, during which the breathable foam continuously dries out by releasing the water as water vapor without causing any damage, the foam will reach its optimal thermal insulation level and notably dampen even ambient noise.

Sustainable insulation over the entire life cycle

The dry foam, which has a bulk density of 30 g/L, sticks to the inside of the wall surfaces, preventing the material from sagging. It is hydrophobic and does not absorb any liquid water. However, water vapor can continue to diffuse through the open pores of the foam, while part of the water vapor can also be stored in the foam itself. The foam adapts to ambient climate changes, even regulating ambient moisture, and can help contribute to a better indoor climate. The dried foam consists of 90% inorganic components, meaning it is non-combustible and can be disposed of with construction waste during demolition or reused as foundation material.

Cavipor®: a highly profitable investment –

economically and ecologically

The measure of subsequent energy-efficient renovation of existing buildings by insulating the core layer usually has a short amortization period and is therefore a highly profitable investment – economically and ecologically.

Learn more at the Cavipor® Academy

Downloads and technical information

Cavipor® is the world's first 3-component system for the production of mineral-based in-situ foam. It was developed during eight years of intensive research with over 5000 test formulations at BASF and extensively patented. The system is approved by the building authorities in Europe (ETA-19/0240).

Get in touch with the Cavipor® team

Questions and Answers about Cavipor®

.png)

.png)

.png)